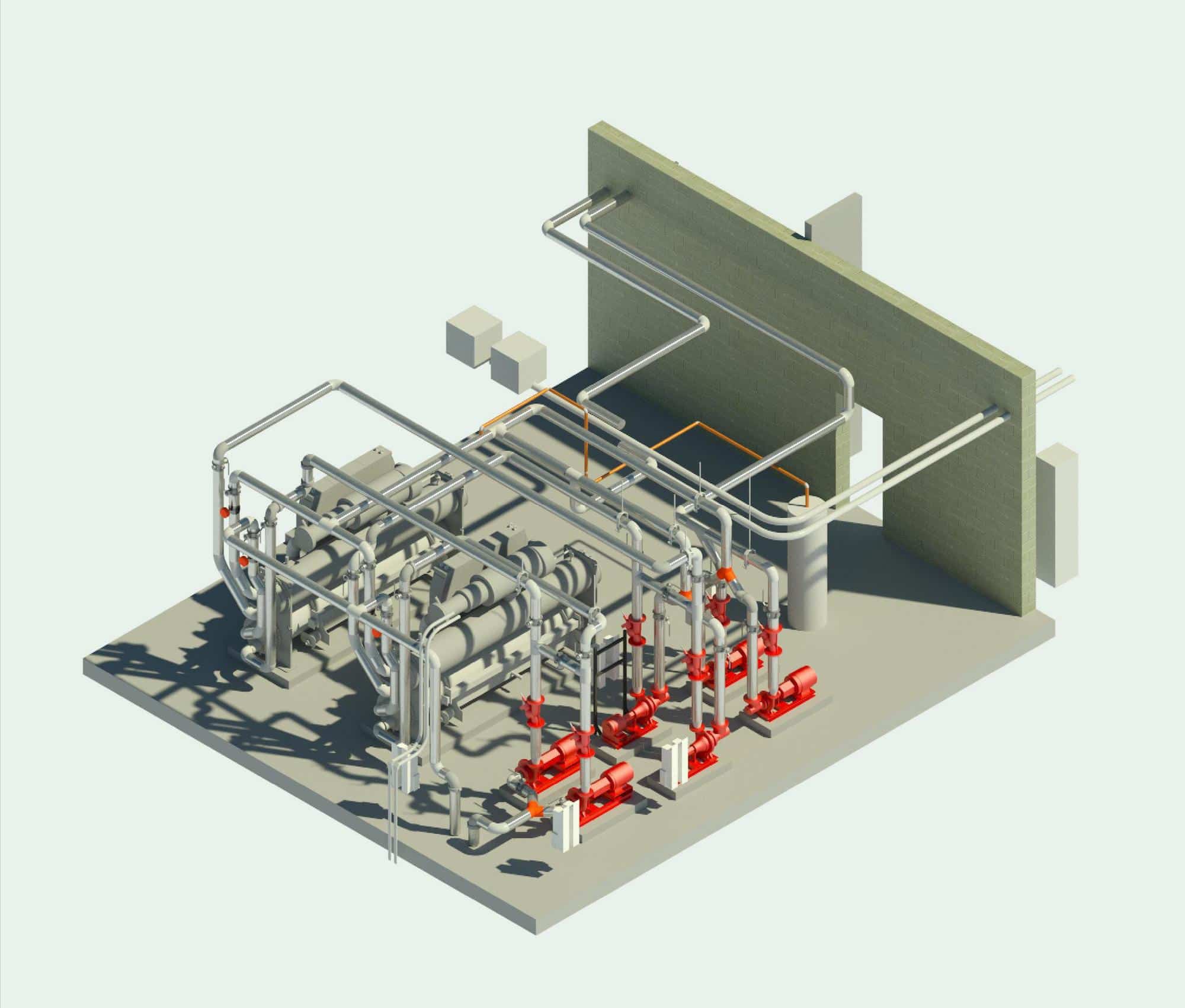

The college dormitory complex featured a redundancy system consisting of dual 180-ton chillers. To enhance the efficiency and functionality of the existing system, the services of ING engineering were engaged to conduct a comprehensive assessment and develop a two-phase replacement strategy. The outdated chillers were replaced with state-of-the-art, energy-efficient magnetic bearing chillers known for their superior performance and reduced noise levels. The renovation of the expansive mechanical room encompassed various aspects, including foundation pads, control systems, and safety measures, ensuring a comprehensive upgrade of the entire facility.